Needle Options

… and when to use them!

Ever wonder, am I using the correct needle for the job?

Here are some quick notes about needles.

SHARP POINT or SHARP TIP NEEDLE:

The standard needle used in embroidery is a sharp tip 75/11.

The 75/11 works best with the standard 40 wt. embroidery thread. This will work for most products and fabric types such as twill, fleece, and t-shirts.

BALLPOINT NEEDLE:

Ballpoint needles can help prevent snagging on knit fabrics such as pique, loose knits, and beanies.

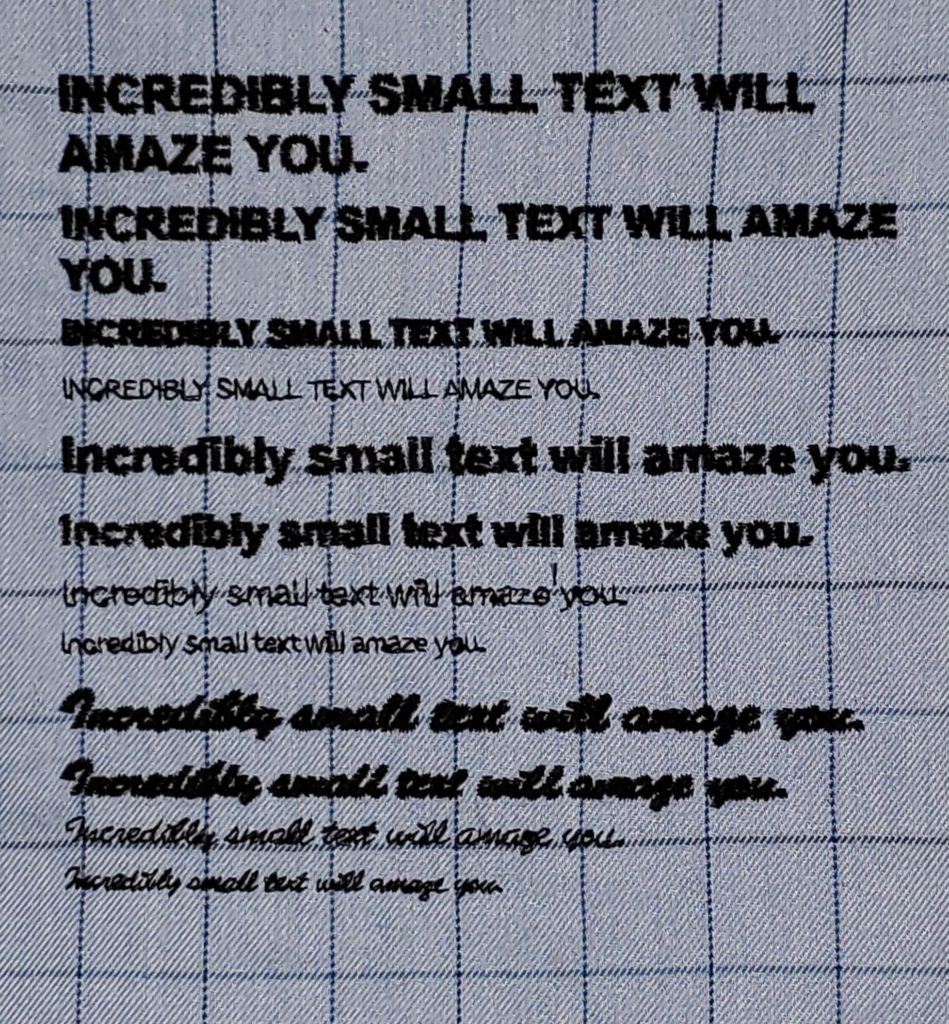

SHARP, CLEAN, SMALL LETTERING:

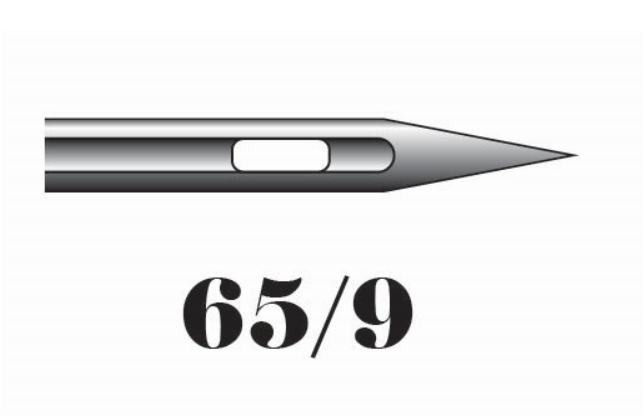

And finally, for a sharper look, or for cleaner small lettering, we suggest you try the 65/9 needle with 60 wt. thread.

REMEMBER FOR BEST RESULTS:

When ordering a design, always let us know what part of the logo you plan on using 60 wt. threat and 65/9 needles, so we can adust the density.

* EXPERT TIP: Always keep different spare needles on hand even if you don’t use them often. They could come handy in a pinch!

0 comments on article "Needle Options"