Small Lettering Guide – Part 1

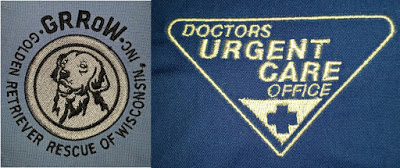

Twill/Denim/Nylon

With fabrics such as twill, denim, or nylon, embroidery does not sink much and generally floats on top of the fabric. This creates less of a need for underlay and shorter pull compensation, thus allowing us to go smaller with text than other fabrics.

What Is The Smallest I Can Go?

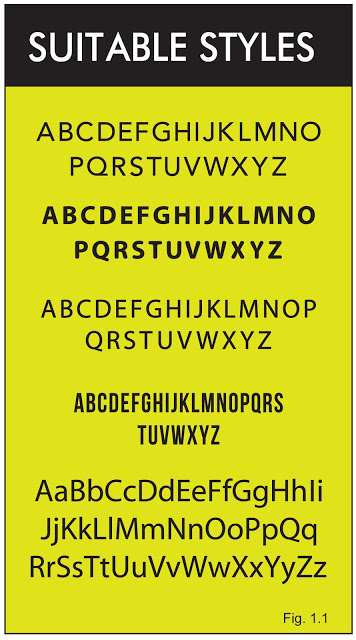

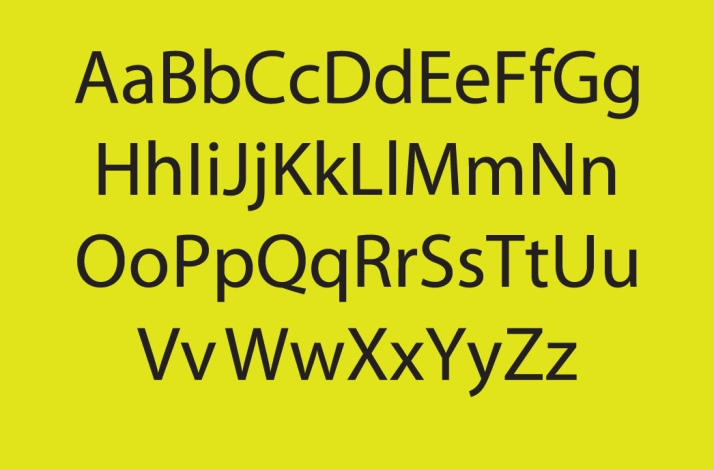

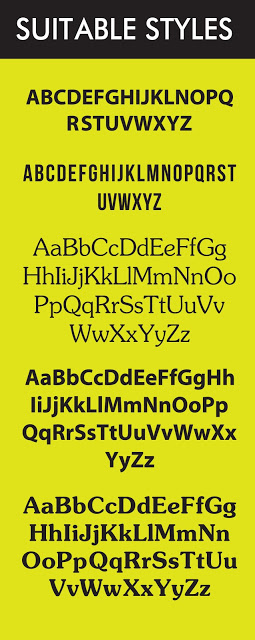

Absolute minimum height for all caps is 5mm/.18. Absolute minimum for upper and lower case letters is 6.2mm/.24″. Letter stroke can be no smaller than .66mm/0.24, as seen below:

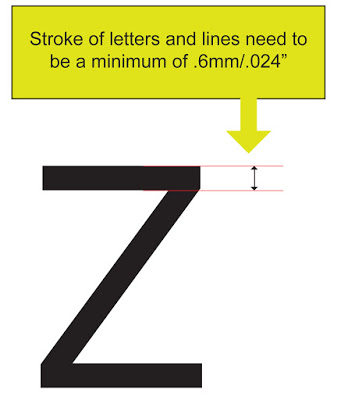

Do You Have Examples Of Good And Bad Text?

We do! Check out below the difference following our advice can make:

Fleece/Heavy Knits/Towels

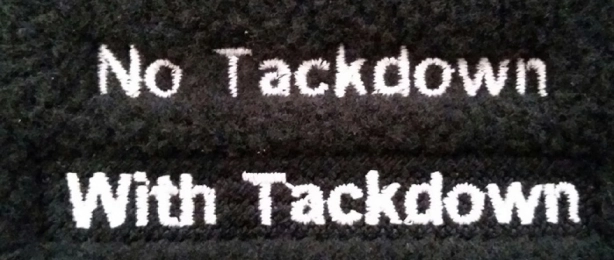

Fabrics such as polar fleece, towels and heavy knits like beanies can create a lot of issues when embroidering. First of all, the polar fleece and heavy knits have plenty of stretch. Second, all three types have a pile that can distort or hide the embroidery.

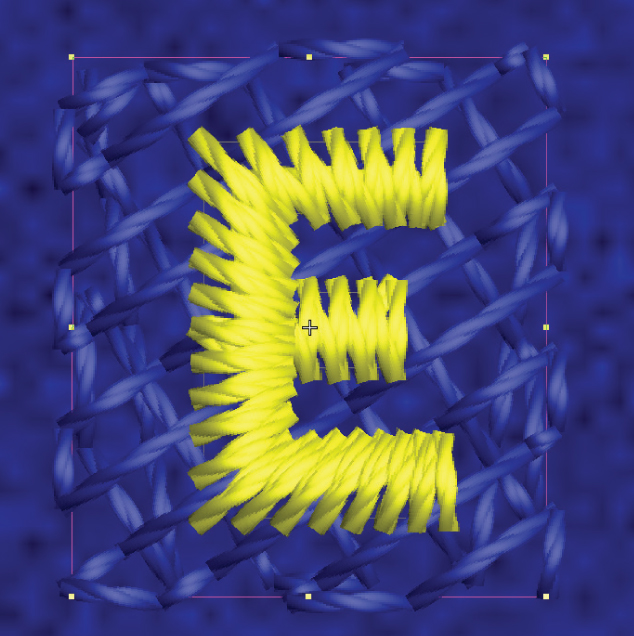

Underlay can prevent the letters from sinking and distorting their shapes, however thinner strokes do not have enough room for the type and amount of underlay needed (fig 3.2.)

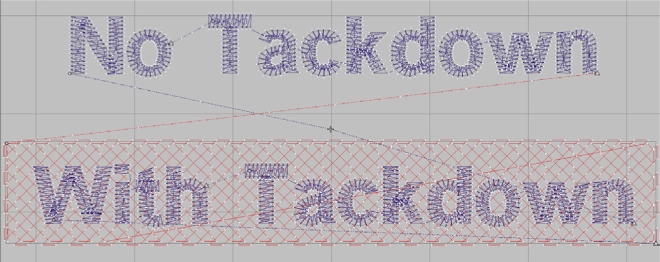

This is where tackdown comes in. Tackdown is an open layer of ceeding (also known as Tatami or fill stitch) laying down in one direction and again in the opposite direction to make an x pattern that provides a more stable surface for the embroidery (fig. 3.1, 3.3, and 3.4.)

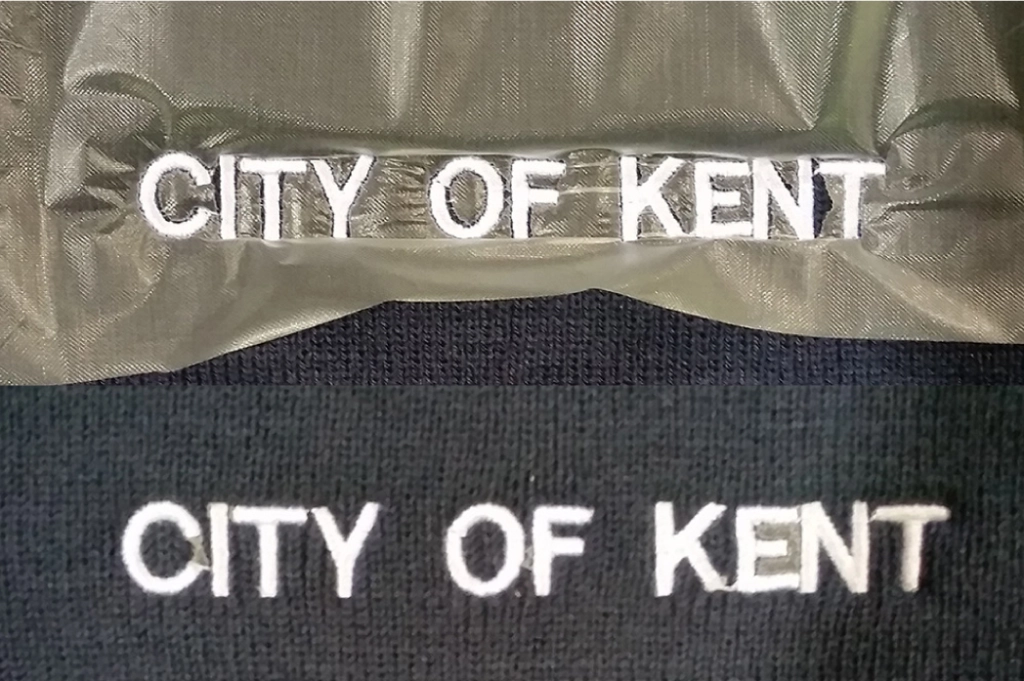

Tackdown keeps the letters from sinking as much and also makes a barrier away from the letters to keep high pile fabric from covering the embroidery. Without tackdown, you will need bigger and bolder letters (fig. 4.1.) Even then, there may still be issues some issues with the fabric peaking through or over letters.

Making the tatami stitch open reduces the amount of stitches. The tackdown is always meant to match the color of the garment so it is less obtrusive than just a box of regular tatami stitching.

Tackdown can be any shape you want and can go around an entire logo if necessary.

Sometimes you just can’t use tackdown. Maybe size does not allow it, or the customer just doesn’t like it, or if you are using stock lettering that just isn’t coming out right. If you find yourself with a design that isn’t working try a water soluble topping (fig. 4.2 and 4.3.)

Just apply a layer or two to the surface of the fabric and start embroidering. To remove the topping, tear it away and pick out as much remaining pieces as you can. Then lightly dab with wet cloth or steamer.

Polos/Pique/Performance Wear

Pique, tees, and performance wear are stretchy and small lettering gets more difficult. With these fabrics, there is a need for more underlay. Underlay will help stabilize the stretchines and in the case of pique and tees, also prevent excessive sinkage.

Absolute Minimum Height for All Caps is 5.5mm/.21”

Absolute Minimum for Upper & Lower Case Letters is 6.2mm/.24”.

Letter stroke can be no smaller than .6mm

0 comments on article "Small Lettering Guide – Part 1"