Working with 3D Puff Embroidery – Part 4

Embroidering Puff Designs: To Be or Not to Be?

Now that you have learned all about basic puff embroidery, let’s get down to business on more complex details.

To start, let’s talk about the “Rules of Puff”:

Rule Number 1: Always Use Satin Stitches

- You should always use satin stitches to get that raised effect.

- We use satin stitches because fill stitch (also known as: Tatami, Ceeding) for all intents and purposes will stomp down the foam. This rules out doing most complex shapes.

- Remember, embroidery machines will have a limit of 12 mm to 21 mm for the maximum width of satin stitches.

Rule Number 2: Avoid Complex Shapes and Thin Lines

- Puff works best with columns, not complex shapes. A complex shape can be a shape with many appendages, or holes.

- Complex shapes are best built with fill stitches, but as you now know, fill stitches will just flatten the image.

- Try avoiding thin lines in puff. The thinner the line, the less room there is for capping the ends. The thin lines will push the foam down, so the finished result will have less height than with wider stitches.

Rule Number 3: Think Through All Aspects of Your Foam

- Using the wrong foam color will give you inferior results. As you know, no matter what density, foam has a tendency to stick out, which is why we choose the color of foam closest to the top stitching. This makes producing multi-colored puff designs difficult. I recommend staying away from using more than one color of puff, but if you must, here are some guidelines that may help:

- Leave approximately a ¼ inch gap between the puff colors. No puzzle pieces. You must be able to cut the foam into simple curved or straight shapes.

- Don’t overlap two colors of foam or the output will be undesirable. Instead, pick one color of foam and hope for the best. Also, let our staff know beforehand what you are planning, so we can look for and avoid any potential pitfalls.

- Another thing to look out for: avoid overlapped puff shapes on the front seam. Tension from the combined output could result in thread breaks and bird’s nesting in the back.

- Stacking or overlapping foam is a no-no.

Rule Number 4: Auto-Split Stitches

- Turn off auto-split stitches to get a smooth look. We limit the width of the puff to be under 12 mm for the default maximum length before your machine turns a stitch into a trim. If you know your machine can go greater than that, feel free and let us know how wide the stitch can be.

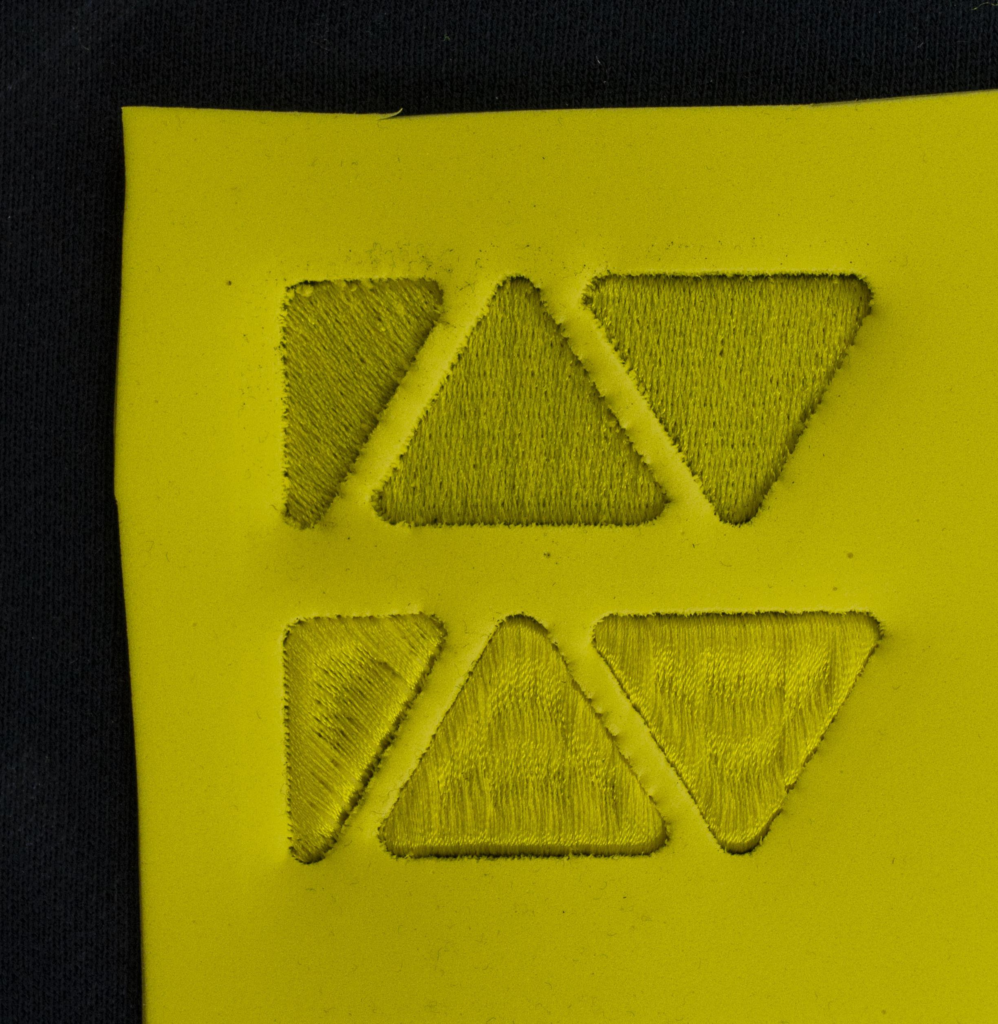

- Another way to prevent wide stitches from becoming trims is the auto-split stitch. We try to avoid using this because it gives an unwanted pattern. Here are some examples of auto- split stitch below. While fill stitches allow you to go wider, they will result in a flattened product. Using auto-split stitches makes it possible to use satin stitches, but the results will vary.

In the end, the simplest approach will give you the best results. Letters work so well with puff because cutting the shapes into sections won’t be as distracting as with images or complex shapes. Multi-colored puff designs can be tricky, as it is best to not have the colors touching.

If you still have questions, feel free to reach out to our qualified team of experts for advice. We are here to help.

# # #

Author: Jesse Elliott

Over 30 years of experience in digitizing embroidery and screen printing

0 comments on article "Working with 3D Puff Embroidery – Part 4"