The Art of the Dot: Why Halftones Matter More Than You Think

Ever wonder how printers achieve smooth gradients and realistic shading using only one ink color? The secret lies in halftones — the tiny dot patterns that turn solid ink into subtle tonal variations.

What are Halftones?

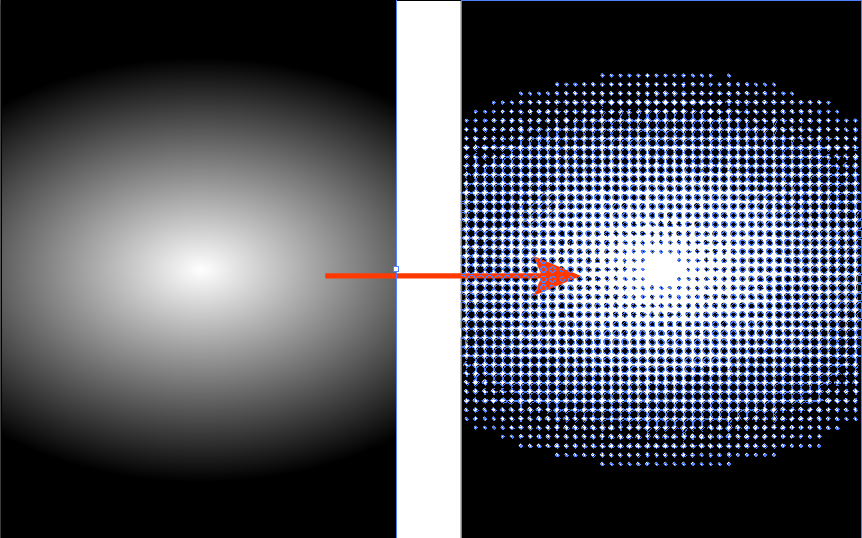

Halftones are dot patterns used to simulate tonal variation with a single ink color. By varying dot size and frequency, halftones create the perception of gradients and shading. Smaller dots produce lighter values, while larger or more closely spaced dots yield darker values. This method allows printers to reproduce a wide range of tonal values without adding additional spot colors or increasing the number of screen separations.

Why You Should Create the Halftones

When we deliver artwork, we provide clean color values but do not create the halftone dot patterns. That’s because halftone structure is dependent on multiple variables that differ from printer to printer: mesh count, ink type, screen tension, substrate, and press setup all play a role in determining the optimal dot size and frequency.

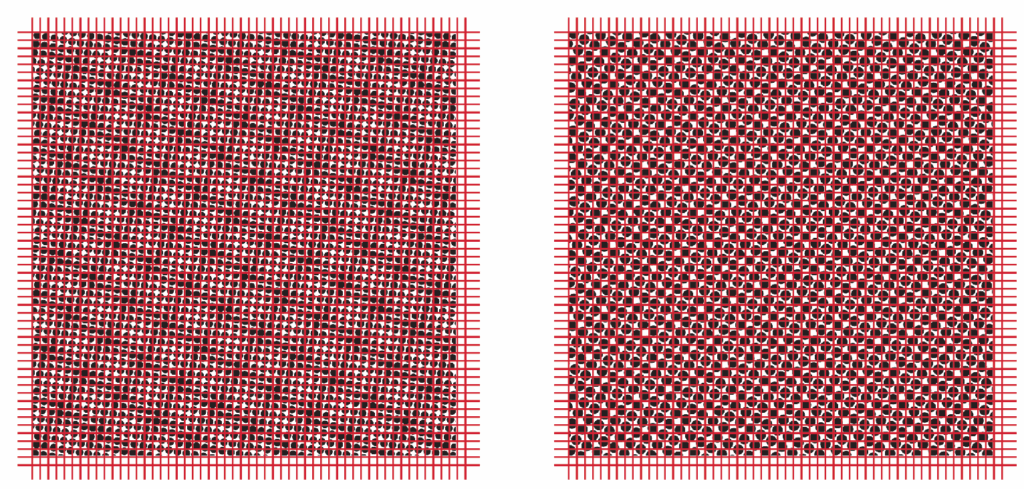

If we create vector halftones, it would be difficult for us to create the size of halftones you want and as shown on the right, the dots will be vector shapes and won’t be editable.

Instead, halftones should be generated at the production stage using RIP (Raster Image Processor) software. The RIP applies halftone settings based on the printer’s specific requirements, ensuring consistent dots-per-inch (DPI), angle, and shape. If halftones were embedded into the artwork, any change in mesh count or screen size would require manual reprocessing—adding unnecessary time and cost. By leaving halftone generation to the RIP, you maintain flexibility, precision, and production efficiency.

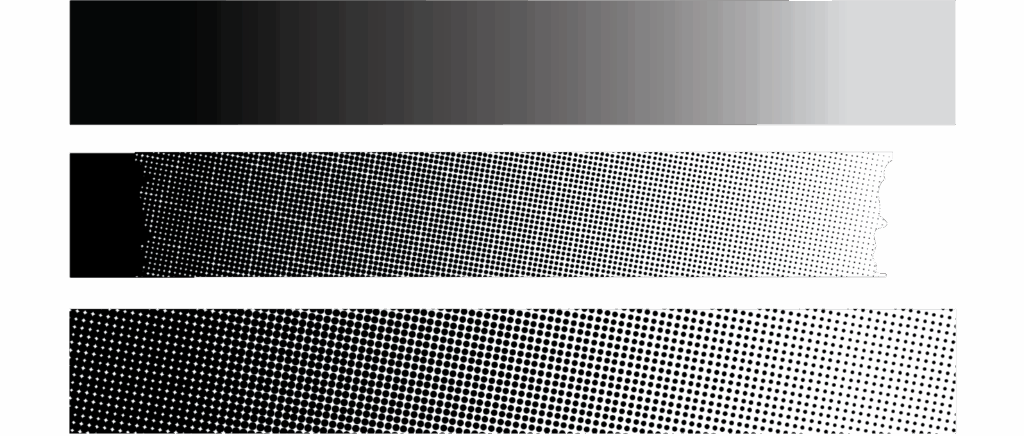

Seeing Drop Off? Might Be Your Dots are Too Small.

When screen printing, drop off can happen if the dots are too small. The top strip is the artwork, the middle strip is what it may look like printed if the halftone is too small. The bottom shows a larger halftone with a more even gradient.

Halftones may be tiny, but their impact is huge. Each dot works in harmony with countless others to bring your artwork to life. By trusting your printer to set them up correctly, you’re not giving up control — you’re collaborating for the best possible result on press.

0 comments on article "The Art of the Dot: Why Halftones Matter More Than You Think"